Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

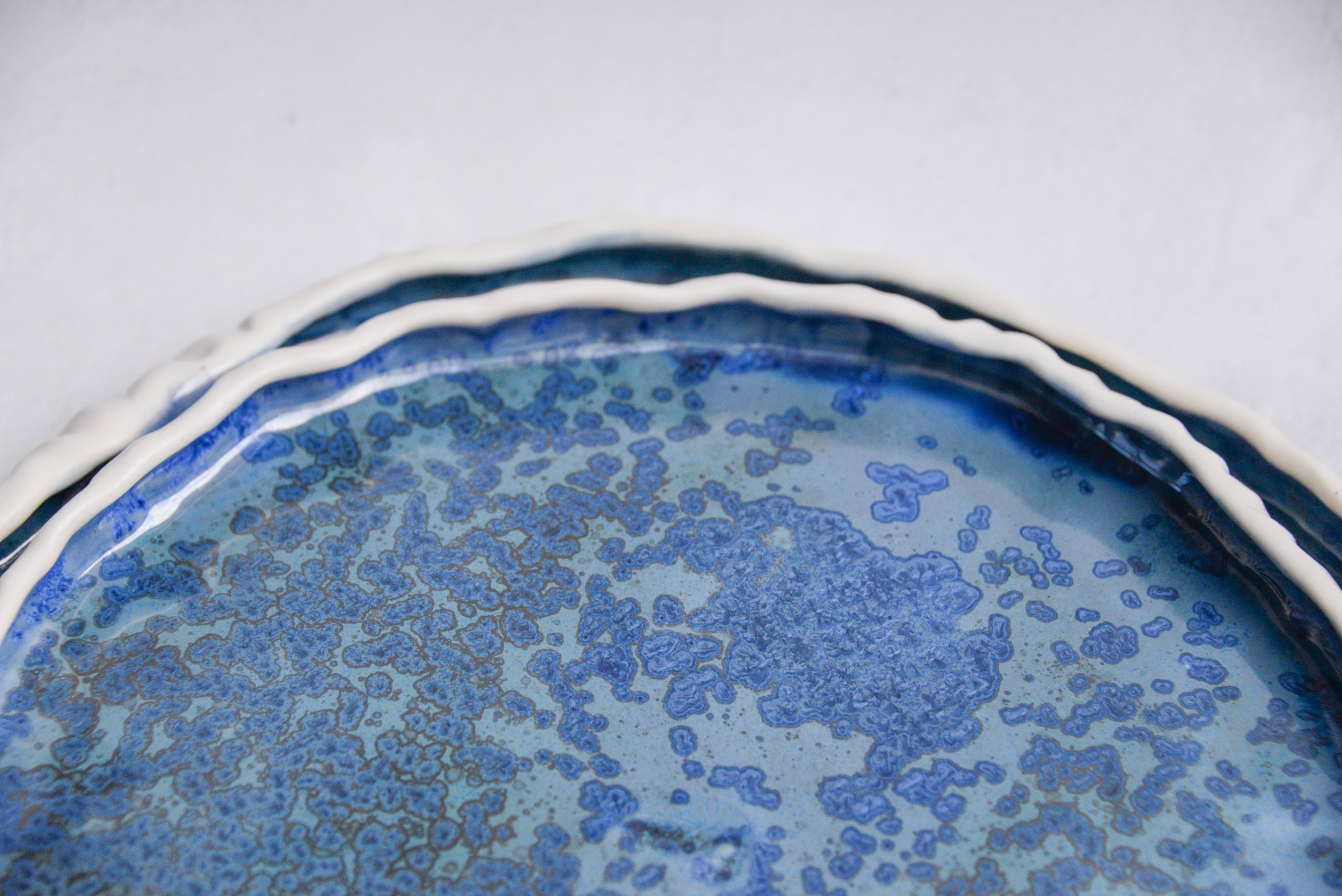

"Bright Turquoise Matte" Glaze — Dry Powder

A vibrant turquoise matte glaze that brings luminous colour and soft, velvety texture to porcelain and stoneware. Beautiful on its own, and exceptional when layered with specialty glazes for added crystalline depth.

In the photos:

• Image 1: Turquoise glaze layered with Matte Crystal Glaze and applied over volcanic glaze (brush application).

• Image 2: Turquoise glaze on its own on porcelain (Audrey Blackman).

Video demonstration: https://www.instagram.com/p/CuuB43lOERK/

Lead-free • Cadmium-free

Suitable for porcelain and high-fired stoneware.

Recommended Firing Range

1220–1280°C (≈ 2228–2336°F)

Cone 6–9 equivalent

How to Achieve the Pictured Effect

To recreate the layered surface shown:

Apply Turquoise Matte Glaze as your base.

While dry or nearly dry, add a second layer of Matte Crystal Glaze in selected areas to encourage crystal formation and matte breakup.

Important Food-Safety Note:

“Matte Crystal Glaze” is not food-safe (though lead- and cadmium-free).

It should be used only on exterior surfaces of functional ware, as demonstrated in your pieces.

Sold in Powder Form Only

Price per 0.5 kg (500 g).

Mixing Guidelines

Begin with a 1:1 water-to-powder ratio.

Sieve well.

Adjust with a little extra water if needed to reach your preferred consistency.

IMPORTANT:

Mix the entire dry bag at once — because the glaze is hand-blended, taking only part of the batch will result in uneven ingredient distribution.

Yield estimate:

500 g (≈ 1.1 lb) dry powder → approx. 800 ml (≈ 27 fl oz) liquid glaze.

Application Notes

• Suitable for dipping, pouring, brushing, or spraying.

• Brush application creates layered, varied tonal edges — ideal for combining with volcanic glazes.

• Works beautifully on porcelain, white stoneware, and textured surfaces.

• Turquoise shifts slightly depending on clay body and thickness.

Safety Warning

• Do not ingest.

• Wear gloves when mixing or applying.

• Avoid contact with eyes; rinse thoroughly if it occurs.

• Prevent glaze dust — do not sweep dry material; clean with a wet cloth.

• Ensure good ventilation during firing.

A vibrant turquoise matte glaze that brings luminous colour and soft, velvety texture to porcelain and stoneware. Beautiful on its own, and exceptional when layered with specialty glazes for added crystalline depth.

In the photos:

• Image 1: Turquoise glaze layered with Matte Crystal Glaze and applied over volcanic glaze (brush application).

• Image 2: Turquoise glaze on its own on porcelain (Audrey Blackman).

Video demonstration: https://www.instagram.com/p/CuuB43lOERK/

Lead-free • Cadmium-free

Suitable for porcelain and high-fired stoneware.

Recommended Firing Range

1220–1280°C (≈ 2228–2336°F)

Cone 6–9 equivalent

How to Achieve the Pictured Effect

To recreate the layered surface shown:

Apply Turquoise Matte Glaze as your base.

While dry or nearly dry, add a second layer of Matte Crystal Glaze in selected areas to encourage crystal formation and matte breakup.

Important Food-Safety Note:

“Matte Crystal Glaze” is not food-safe (though lead- and cadmium-free).

It should be used only on exterior surfaces of functional ware, as demonstrated in your pieces.

Sold in Powder Form Only

Price per 0.5 kg (500 g).

Mixing Guidelines

Begin with a 1:1 water-to-powder ratio.

Sieve well.

Adjust with a little extra water if needed to reach your preferred consistency.

IMPORTANT:

Mix the entire dry bag at once — because the glaze is hand-blended, taking only part of the batch will result in uneven ingredient distribution.

Yield estimate:

500 g (≈ 1.1 lb) dry powder → approx. 800 ml (≈ 27 fl oz) liquid glaze.

Application Notes

• Suitable for dipping, pouring, brushing, or spraying.

• Brush application creates layered, varied tonal edges — ideal for combining with volcanic glazes.

• Works beautifully on porcelain, white stoneware, and textured surfaces.

• Turquoise shifts slightly depending on clay body and thickness.

Safety Warning

• Do not ingest.

• Wear gloves when mixing or applying.

• Avoid contact with eyes; rinse thoroughly if it occurs.

• Prevent glaze dust — do not sweep dry material; clean with a wet cloth.

• Ensure good ventilation during firing.